Beech (Fagus sylvatica)

The Copper Beech (Fagus sylvatica) (European or Common Bech), is a deciduos tree belonging to the beech family (Fagaceae).

Natural range

The Copper Beech, known commonly as the “Beech”, makes up 14% of Germany’s 10.8 million hectares of forest area, making it the country’s most common deciduous tree. They prefer humid locations and lightly acidic to calcified ground with fertile sandy or clayey soil. They tend to avoid very dry ground or waterlogged, regularly flooded locations. In Europe they can be found up to 800 metres above sea level and even at altitudes of 1,000 in the southern Alps.

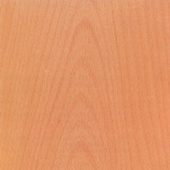

Description of the wood

The Copper beech is one of those tree species with facultative heartwood (red heartwood), which can form when oxygen enters central parts of the tree, i.e. due to damage. Normally, heartwoods and sapwood in healthy beech trees can scarcely be told apart. The wood is greyish-white with a pale yellow to reddish hue. Beech wood is hard, very tough with low elasticity and very strong in the load-bearing sense. Basic density is 0.66 g/cm³ with 15% wood moisture.

Workability

Beech wood is easy and clean to work with. Steamed beech eases barking or slicing (for manufacturing veneers). Steaming also reduces the Beech’s tendency to warp and crack and enables the wood to be shaped and flexed easily.

Durability

Beech wood has no durability at all when exposed to the elements (durability class 5 acc. to EN 350-2) and must therefore be treated with the appropriate preservatives for use outdoors, in railway sleepers, for example.

Treatability

Copper Beech heart and sapwood are easy to treat and can be impregnated without difficulty in pressure processes.

Applications

Beech wood has a variety of uses, as a veneer, for the production of plywood and furniture, as well as in internal design, for doors, etc. As a solid wood it is also used internally in staircases and frequently, due to its extreme hardness, parquet floors. As it is very pliable after steaming, curved components in orthopaedic or ergonomic seating furniture are also made of beech. As a turning timber, beech wood is used to make kitchen utensils - breakfast boards, rolling pins, knife handles, cooking spoons and bowls – and wooden toys.

The triumph of the railways in Europe would have been unthinkable without impregnated beech wood sleepers, which were much cheaper than their oak counterparts. Weaker beech wood is used in wood pulp and paper producing, as well as in the particle and fibre board industries. Beech chippings and wood flour are used for smoking and last, but not least, beech is a high-grade heating fuel with a high calorific value, because it burns long and slowly, forming good, low-burning embers. This, and attractive flame pattern, is why beech is one of the best wood types for open fireplaces.